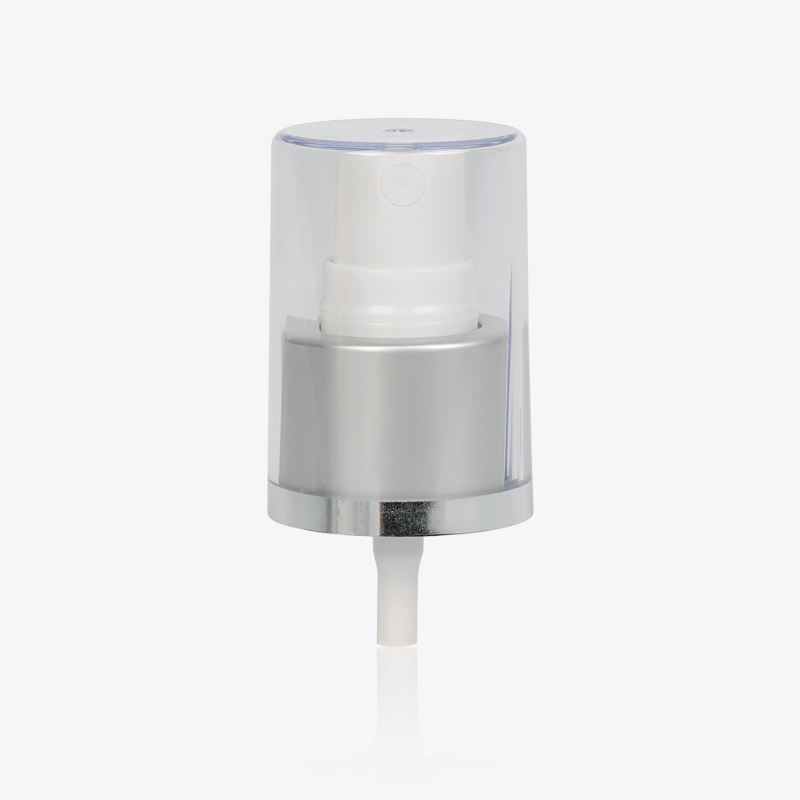

Cosmetic Treatment Pump's composition and working principle

A standard plastic lotion pump usually has 6 parts.

Actuator - Made of polypropylene, also known as the pump head, whose main task is to expel the contents of the lotion pump container when pressurized.

Closure - With which the entire assembly is secured to the neck of the lotion pump.

Outer gasket - usually made of low-density polyethylene or rubber, helps prevent contents from leaking out of the mouth area and is usually a friction fit inside the closure.

Housing - Sometimes called pump assembly housing, it holds all the parts of the lotion pump in one place. The lotion pump housing also doubles as a transfer vessel for transferring the contents from the dip tube to the actuator.

Inner Housing Components (Ball/Spring/Piston/Rod) - The inner housing components of a lotion pump depend on the individual product design and vary from manufacturer to manufacturer.

Dip Tube - This is a long tube made of polypropylene that runs from the nozzle of the lotion pump to the bottom.

How Lotion Pumps Work

STEP 1 - The lotion pump functions like an aspirator. It defies gravity and helps the contents of the tank reach the user's palm.

Step 2 - When the actuator is depressed, the piston moves which in turn compresses the spring. It effectively allows the upwardly applied air pressure to pull the ball upwards along with the contents of the dip tube. The contents first fill the dip tube and then go to the lotion pump chamber.

Step 3 - After releasing the actuator, the spring will reposition to its original position. The ball returns to its standby position and seals the jar, cutting off the flow of the contents so they cannot return to the lotion pump bottle.

step 4 - the above three steps are collectively referred to as start-up. When the actuator is depressed again from its rest position, the container contents will first pass through the valve stem and then reach the actuator. Finally, the pump dispenses the liquid into the user's hands.

Web Menu

Product Search

Exit Menu

news

Cosmetic Treatment Pumps's Composition And Working Principle

Posted by Admin | 20 Jan

Related Products

-

Black Plastic cream Pump mist sprayer 18/415,18/410

Cat:18 Cream Pump

Packaging & Delivery Packaging Details packaging:515*350*305 Port shanghai Lead Time : ...

See Details -

20/410 perfume mist sprayer pump for cosmetic plastic bottle

Cat:24 MIST SPRAYER PUMP

Packaging & Delivery Packaging Details:packaging:515*350*305 Port:shanghai Lead Time: ...

See Details -

18/410 black PP Plastic Treatment Cream Container Pump With Full Cap

Cat:18 Cream Pump

Packaging & Delivery Packaging Details packaging:515*350*305 Port shanghai Lead Time : ...

See Details -

18/410 white ribbed cream pump

Cat:18 Cream Pump

Packaging & Delivery Packaging Details packaging:515*350*305 Port shanghai Lead Time : ...

See Details -

18 / 415 plastic black ribbed treatment cream pump

Cat:18 Cream Pump

Packaging & Delivery Packaging Details packaging:515*350*305 Port shanghai Lead Time : ...

See Details -

18/410 plastic bottle mist sprayer pump with PP lid

Cat:18 MIST SPRAYER PUMP

Packaging & Delivery Packaging Details packaging:515*350*305 Port Shanghai Lead Time : ...

See Details -

18/415 18/410 aluminum fine mist sprayer pump with over cap

Cat:18 MIST SPRAYER PUMP

Packaging & Delivery Packaging Details packaging:515*350*305 Port shanghai Lead Time : ...

See Details -

plastic perfume bottle mist sprayer 18/410

Cat:18 MIST SPRAYER PUMP

Packaging & Delivery Packaging Details The form of packing depends on the customer's needs. ...

See Details -

Fast Delivery Plastic Mist Spray Pump18/410 Atomizer Sprayer

Cat:18 MIST SPRAYER PUMP

Packaging & Delivery Selling Units: Single item Single package size: 10X3X7 cm Single gr...

See Details -

Custom 20/410 metal shampoo pump,treatment pump for oil bottle

Cat:20 Cream Pump

Packaging & Delivery Packaging Details packaging:515*350*305 Port shanghai Lead Time : ...

See Details

So far, the company has formed a complete industrial chain covering product development, automatic injection molding, automatic inspection, and automatic assembly, focusing on Cosmetic Packaging for sale. It has obtained ISO9001 certificate and ISO14001 certificate, and has emerged as a stable and ideal custom Cosmetic Packaging.

Read MoreCopyright © Zhangjiagang Fengsu Cosmetic Packaging Co.,Ltd. All Rights Reserved

简体中文

简体中文 English

English