Plastic Lotion Pump: All You Need to Know

pump parts

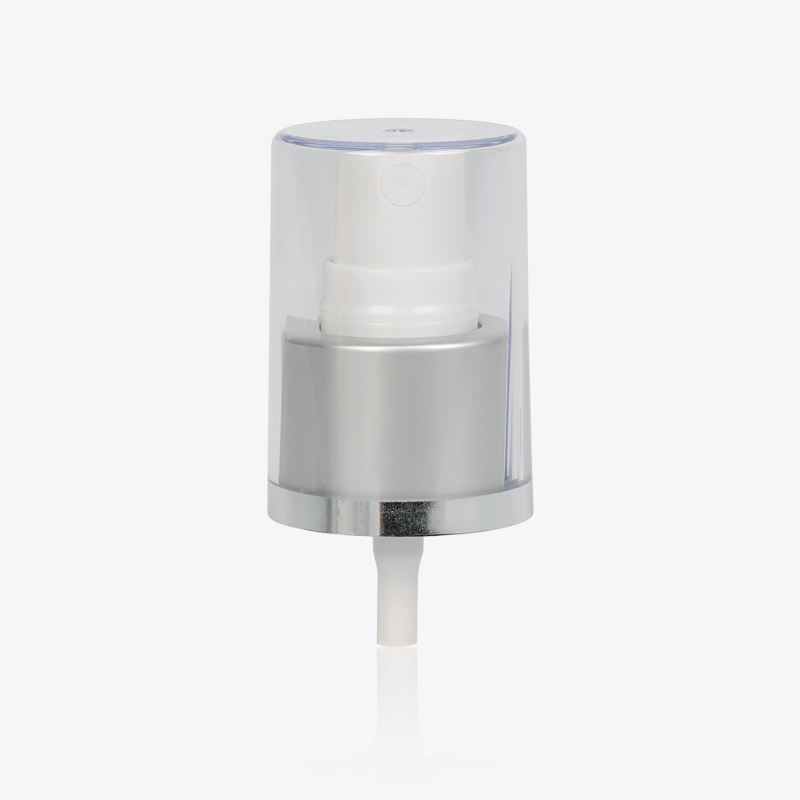

Actuator - The actuator is the top of the pump that you push down to dispense any viscous material inside the container. This is what allows the pump to run. Actuators often have locking mechanisms so that products cannot be accidentally dispensed during shipping or travel. The lotion pump can be locked in the up or down position. Actuators are usually made of polypropylene (PP), a very durable plastic.

Closure - This is the part where the pump is screwed onto the bottle. Lotion pump caps are either ribbed or smooth. The ribbed closure is easier to open because the small grooves allow for a better grip on lotion-covered fingers.

Housing - The housing is the main pump assembly that holds the pump components (pistons, balls, springs, etc.) in place and delivers fluid to the actuator.

Internal Components - Internal components are located within the pump casing. They consist of various components, including springs, balls, pistons, and/or rods, that transfer product from the container through the dip tube into the actuator.

Dip Tube - A dip tube is a tube that extends down into a container. Liquid flows up the tube and out of the pump. It is important that the length of the dip tube matches the height of the bottle. If the tube is too short, you will get a product that cannot be dispensed with the pump. If the tube is too long, then it may not tighten the bottle.

pump output

Pump output is usually measured in cubic centimeters (cc) or milliliters (mL). The output tells you how much liquid was dispensed by each pump. The pump has various output options.

Web Menu

Product Search

Exit Menu

news

Plastic Lotion Pump: All You Need To Know

Posted by Admin | 15 Jul

Related Products

-

20/410 perfume mist sprayer pump for cosmetic plastic bottle

Cat:24 MIST SPRAYER PUMP

Packaging & Delivery Packaging Details:packaging:515*350*305 Port:shanghai Lead Time: ...

See Details -

non spill matte golden 18mm mist sprayer,lotion pump,cream pump

Cat:24 MIST SPRAYER PUMP

Packaging & Delivery Selling Units:Single item Single package size: 500X350X350 cm Single ...

See Details -

18/410 full Cap Shinny Silver aluminum Cream Pump

Cat:18 Cream Pump

Packaging & Delivery Packaging Details packaging:515*350*305 Port shanghai Lead Time : ...

See Details -

plastic material 18/415 aluminum lotion pump oil pump for glass bottle

Cat:18 Cream Pump

Packaging & Delivery Selling Units: Single item Single package size: 52X35X30 cm Single ...

See Details -

Cosmetic packaging 20/410 aluminum outer spring lotion pump

Cat:18 Cream Pump

Packaging & Delivery Packaging Details The form of packing depends on the customer's needs. ...

See Details -

18/410 plastic bottle mist sprayer pump with PP lid

Cat:18 MIST SPRAYER PUMP

Packaging & Delivery Packaging Details packaging:515*350*305 Port Shanghai Lead Time : ...

See Details -

2019 18/410 Aluminum lotion fine mist sprayer pump

Cat:18 MIST SPRAYER PUMP

Packaging & Delivery Packaging Details The form of packing depends on the customer's needs. ...

See Details -

Fancy design 18/410,18/415 aluminum perfume spray pump,screw pump for glass square bottle

Cat:18 MIST SPRAYER PUMP

Packaging & Delivery Packaging Details The form of packing depends on the customer's needs. ...

See Details -

plastic perfume bottle mist sprayer 18/410

Cat:18 MIST SPRAYER PUMP

Packaging & Delivery Packaging Details The form of packing depends on the customer's needs. ...

See Details -

Fast Delivery Plastic Mist Spray Pump18/410 Atomizer Sprayer

Cat:18 MIST SPRAYER PUMP

Packaging & Delivery Selling Units: Single item Single package size: 10X3X7 cm Single gr...

See Details

So far, the company has formed a complete industrial chain covering product development, automatic injection molding, automatic inspection, and automatic assembly, focusing on Cosmetic Packaging for sale. It has obtained ISO9001 certificate and ISO14001 certificate, and has emerged as a stable and ideal custom Cosmetic Packaging.

Read MoreCopyright © Zhangjiagang Fengsu Cosmetic Packaging Co.,Ltd. All Rights Reserved

简体中文

简体中文 English

English