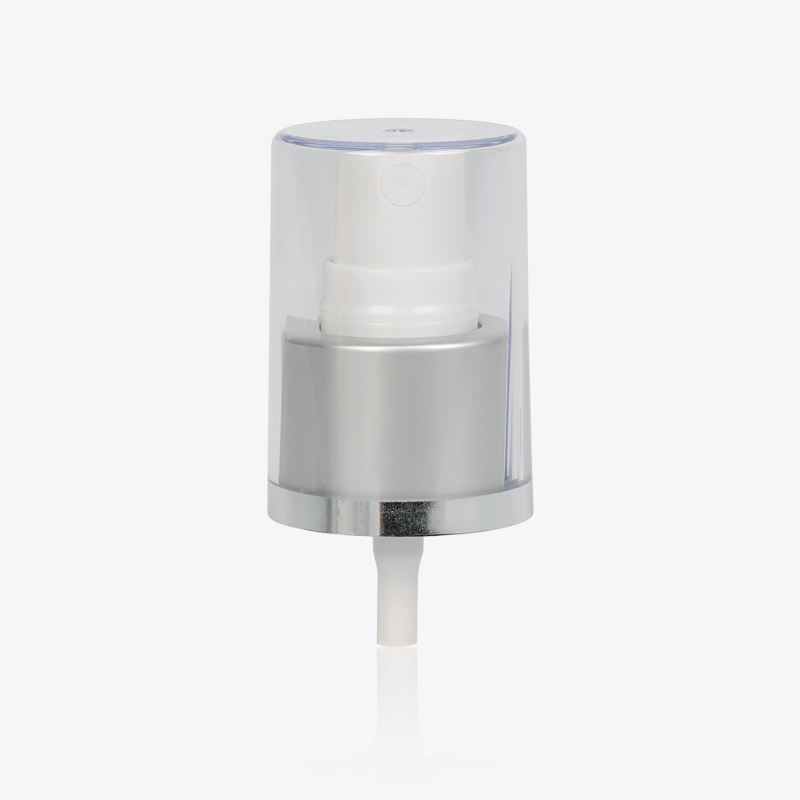

A simple Cream Pump Dispenser is made up of several components that work together to deliver precise amounts of liquid. These components include:

Seal: The part of the pump that attaches to the neck of the bottle, usually with a smooth or ribbed surface

Actuator: This is the top of the pump, also known as the pump head, that is pressed to dispense product

Outer Gasket: Fits inside the cap, usually made of plastic or rubber, and is responsible for preventing the product from leaking

Housing: The main pump assembly that holds the pump assembly in place and delivers fluid to the actuator

Dip Tube: the visible tube extending from the housing to the bottom of the container used to deliver liquid for dispensing

Internal components: various parts including springs, balls, pistons, and/or rods that help move product from the container to the actuator

Mechanics of Soap Pumps

Soap dispensing pumps rely on the components of the bottle and the suction to draw the liquid upwards and defy the laws of gravity.

Each time the actuator is pressed or activated, the piston applies pressure to the spring and moves the ball upwards, taking some of the soap product with it.

When you release the actuator, the piston, and spring return to their rest positions, sealing the housing cavity to prevent liquid from flowing back into the bottle.

Allocation Amount Options

Actuators are designed to meet different output requirements. The output of the product is in milliliters (ml) or cubic centimeters (cc).

These measurements are important for correct dosing, with outputs ranging from as small as 0.5 cc to as large as 8 cc. Depending on the type of product you are bottling, you can order the type of pump output that best suits your needs.

Web Menu

Product Search

Exit Menu

news

What Is The Composition And Function Of The Cream Pump Dispenser

Posted by Admin | 30 Dec

Related Products

-

20/410 perfume mist sprayer pump for cosmetic plastic bottle

Cat:24 MIST SPRAYER PUMP

Packaging & Delivery Packaging Details:packaging:515*350*305 Port:shanghai Lead Time: ...

See Details -

18/410 plastic cream pump with square cap

Cat:18 Cream Pump

Packaging & Delivery Packaging Details The form of packing depends on the customer's needs. ...

See Details -

18/410 plastic cream pump lotion pump cap for cream pump bottle

Cat:18 Cream Pump

Packaging & Delivery Packaging Details packaging:515*350*305 Port shanghai Lead Time : ...

See Details -

18mm UV silver Cosmetic plastic cream pump with glass bottle

Cat:18 Cream Pump

Packaging & Delivery Selling Units: Single item Single package size: 52X35X30 cm Single ...

See Details -

18/410 white ribbed cream pump

Cat:18 Cream Pump

Packaging & Delivery Packaging Details packaging:515*350*305 Port shanghai Lead Time : ...

See Details -

18/410,20/410,24/410 Aluminum UV mist spray essential oil treatment pump

Cat:18 MIST SPRAYER PUMP

Packaging & Delivery Selling Units: Single item Single package size: 10X3X7 cm Single gr...

See Details -

18/410 golden aluminum spray pump external spring for perfume and cosmetic pump

Cat:18 MIST SPRAYER PUMP

Packaging & Delivery Packaging Details packaging:515*350*305 Port shanghai Lead Time : ...

See Details -

20/410 matte silver custom color aluminum material lotion cream pump

Cat:20 Cream Pump

Packaging & Delivery Packaging Details The form of packing depends on the customer's needs. ...

See Details

So far, the company has formed a complete industrial chain covering product development, automatic injection molding, automatic inspection, and automatic assembly, focusing on Cosmetic Packaging for sale. It has obtained ISO9001 certificate and ISO14001 certificate, and has emerged as a stable and ideal custom Cosmetic Packaging.

Read MoreCopyright © Zhangjiagang Fengsu Cosmetic Packaging Co.,Ltd. All Rights Reserved

简体中文

简体中文 English

English